Finding the Right Provider for Welding Inspection Madison: Trick Considerations

Finding the Right Provider for Welding Inspection Madison: Trick Considerations

Blog Article

Exactly How Reliable Welding Inspection Improves Structural Stability and Longevity

In the world of construction and engineering, the importance of welding examination can not be overstated, as it plays a critical function in making certain structural stability and expanding the lifespan of jobs. Sign up with the exploration of just how efficient welding evaluations can change potential vulnerabilities right into toughness, adding to the long-lasting success of constructions.

Relevance of Welding Evaluation

Making certain the structural honesty and safety of bonded constructions mandates extensive welding inspection processes. Welding examination serves as an essential safeguard in the building and construction and manufacturing markets, where the stamina and toughness of joints dramatically affect the overall performance of frameworks.

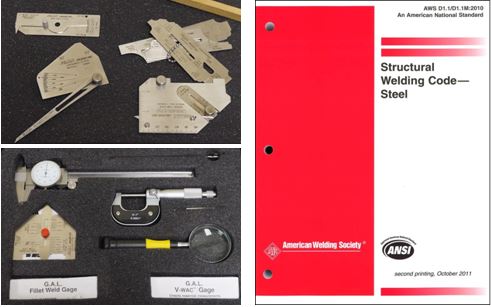

In addition to safety and security, welding evaluation plays an important role in high quality assurance. By adhering to fixed standards, evaluations determine the uniformity of welds, making certain that each satisfies the preferred toughness and visual needs. This consistency is important not only for security however likewise for preserving the track record and dependability of producers and producers. Regulatory conformity is a significant vehicle driver of welding evaluation practices. Market standards and codes, such as those from the American Welding Society (AWS) or the International Company for Standardization (ISO), necessitate adherence to strict standards, underscoring the value of inspections in meeting these specialist and legal responsibilities.

Secret Examination Strategies

Ultrasonic Testing (UT) uses high-frequency audio waves to spot subsurface problems, supplying precise information regarding weld honesty without creating any damage. Radiographic Checking (RT), entailing X-rays or gamma rays, gives a detailed photo of the weld's interior framework, disclosing surprise blemishes. Magnetic Particle Testing (MPT) is another non-destructive technique, specifically reliable for spotting surface and near-surface interruptions in ferromagnetic products.

Penetrant Screening (PT) entails the application of a fluid color to disclose surface-breaking flaws, supplying a cost-effective and uncomplicated remedy for non-porous products. Each strategy has its certain applications, staminas, and limitations, and often a combination of methods is employed to accomplish comprehensive examination results. Proficiency of these strategies boosts the integrity and toughness of welded frameworks, aligning with safety and efficiency assumptions.

Identifying Common Problems

Porosity, identified by gas pockets within the weld, reduces the weld's strength and sturdiness. Splits, which can occur during or after welding, position considerable dangers due to their possible to propagate under stress and anxiety.

Insufficient combination, where the weld steel stops working to bond completely with the base material, undermines the architectural honesty, leading to weak joints. Slag additions happen when non-metallic materials are trapped in the weld, compromising its toughness and top quality.

Determining these flaws through meticulous inspection approaches, such as aesthetic assessment, ultrasonic testing, or radiography, is essential. Dealing with these concerns ensures weld top quality, eventually supporting the architectural honesty and security of the built environment.

Enhancing Architectural Performance

Recognizing the importance of recognizing typical weld issues normally brings about discovering methods for improving architectural performance. The foundational strategy for improving performance requires employing sophisticated welding strategies and products that reduce problem occurrence. Utilizing top notch this page filler materials and guaranteeing correct warmth control can substantially minimize concerns such as porosity and cracking, thus improving you can try these out the weld's honesty.

Including state-of-the-art welding innovations, such as laser welding and rubbing mix welding, more amplifies structural resilience. These methods provide remarkable accuracy and lowered thermal distortion, straight influencing the resilience and stamina of the welded structures. Additionally, embracing automated welding systems can make sure repeatable and constant weld high quality, lessening human error.

Additionally, implementing rigorous pre-weld and post-weld treatments is critical. Correct joint layout, surface area preparation, and stress-relieving processes contribute to optimum weld efficiency. Carrying out extensive pre-weld assessments enables early discovery of possible problems, helping with timely improvements prior to they jeopardize the structure.

Lasting Advantages of Evaluation

With watchful inspection techniques, the long-term advantages to architectural integrity come to be progressively noticeable. Constant and comprehensive welding inspections play a critical function in protecting against structural failings by determining inconsistencies and issues early in the construction process. This proactive strategy ensures that prospective concerns are dealt with before they can endanger the safety and durability of structures. By capturing defects early, pricey repairs and downtime are decreased, ultimately expanding the life-span of the infrastructure.

Furthermore, regular inspections contribute to keeping conformity with industry standards and guidelines, thereby staying clear of financial and legal consequences. This adherence to quality control not just improves the reliability of the structure however also cultivates count on amongst stakeholders, consisting of customers, engineers, and governing bodies. The detailed paperwork of assessment end results offers as a useful source for future maintenance and fixing efforts, promoting educated decision-making.

Additionally, reliable inspection practices support technology Your Domain Name by integrating innovative innovations such as non-destructive testing and digital imaging, which can enhance precision and efficiency. This technical integration even more emphasizes the commitment to quality in architectural integrity. Eventually, purchasing careful welding inspections is a prudent technique that produces substantial long-lasting benefits, safeguarding both the economic and physical financial investment in infrastructure tasks.

Conclusion

Reliable welding inspection plays an important function in enhancing structural integrity and durability by identifying problems early in the building process. Using techniques such as aesthetic examination, ultrasonic screening, and radiographic testing guarantees the discovery of problems like fractures and porosity that jeopardize weld strength. Strenuous assessments ensure conformity with market requirements, consequently extending the lifespan of frameworks, lessening expensive repair work, and fostering stakeholder count on the integrity and safety and security of welded building and constructions.

In the world of building and construction and engineering, the relevance of welding inspection can not be overstated, as it plays a crucial function in guaranteeing structural honesty and extending the life expectancy of jobs.Guaranteeing the structural stability and safety and security of welded buildings mandates rigorous welding evaluation processes.Building upon the relevance of welding assessment in securing architectural stability, recognizing the essential examination strategies ends up being essential for reliable application. Reliable welding evaluation encompasses a variety of approaches made to examine weld high quality, making sure compliance with rigorous design requirements - Welding Inspection Madison.Efficient welding examination plays a critical function in improving architectural integrity and longevity by recognizing problems early in the construction procedure

Report this page